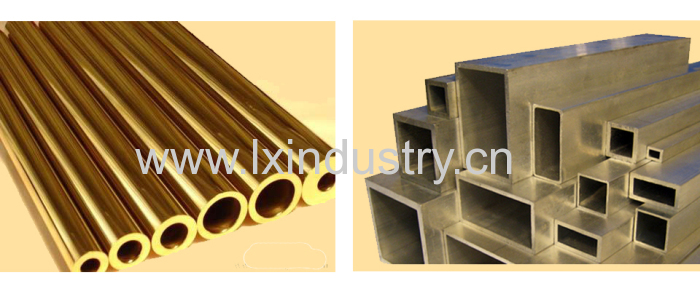

Brass pipe widely used in bathroom accessories, hardware tools manufacturing, auto fittings, heating elements, construction, ship building etc. We offer brass pipe as clients' requirements, manufacturing according to main countries' standards, such as ASTM B 135-02, ASTM B111, GBT 5231-2001, BS EN 13600-2002, etc. 1. Those alloys are specified having the following nominal compositions: Alloy No. | Copper | Zinc | Lead | Tin | C22000/CuZn10 | 90% | 10% | ...... | ...... | C23000/CuZn15 | 85% | 15% | ...... | ...... | C26000/CuZn30 | 70% | 30% | ...... | ...... | C26200/CuZn32 | 68% | 32% | ...... | ...... | C27000/CuZn35 | 65% | 35% | ...... | ...... | C27200/CuZn37 | 63% | 37% | ...... | ...... | C27400/CuZn38 | 62.5% | 37.5% | ....... | ...... | C28000/CuZn40 | 60% | 40% | ...... | ...... | C33000 | 66% | 33.5% | 0.5% | ...... | C33200 | 66% | 32.4% | 1.6% | ...... | C37000 | 60% | 39% | 1.0% | ...... | C44300/CuZn28Sn | 71.5% | 27.5% | ...... | 1% |

2. Specification Available: Alloy No. | Product | Temper | Dimension (mm) | Length (mm) | OD | WT | C21000 | Drawn Tubes | Soft, 1/2 Hard, Hard | 5~200 | 0.5~15 | When OD≤100, L: 1000~7000; When OD≥100, L: 500-6000 | C22000 | C26000 | 15~100 | 0.75~10 | C26200 | C23000 | 10.29~114.3 | 1.57~6.35 | 500~ 6096 | C26800 | 6~280 | 0.8~17.5 | When OD≤100, L: 1000~7000; When OD≥100, L: 500-6000 | C27000 | C28000 | C68700 | Soft, 1/2 Hard | 8~76 | 0.8~4.5 | 2000~14000 | C44300 | C44400 | C44500 |

3. Mechanical Properties of Drawn Temper Tube as following: Copper Alloy | Temper Designation | OD In. | Thickness In. | Tensile Strength Ksi | Rockwell Hardness 30T | Standard | Former | C26000/CuZn30 C27000/CuZn35 C27200/CuZn37 C27400/CuZn32 | H58 | Drawn(GP) | all | all | 54 min | 53 min | H80 | Hard Drawn | Up to 1 | 0.02 to 0.12 | 66 min | 70 min | H80 | Hard Drawn | Over 1 to 2 | 0.035 to 0.18 | 66 min | 70 min | H80 | Hard Drawn | Over 2 to 4 | 0.06 to 0.25 | 66 min | 70 min | C44300/CuZn28Sn | H58 | Drawn(GP) | all | all | 54 min. | 53 min. | H80 | Drawn(GP) | all | all | 66 min. | 70 min. |

4. Mechanical Properties of Annealed Temper Tube as following: Copper Alloy | Temper Designation | Thickness In. | Rockwell Hardness | Average gain Size(mm) | Standard | Former | Scale | Max. | Min. | Max. | C26000/CuZn38 | O60 | Soft Anneal | Up to 0.03 | 30T | 40 | 0.025 | 0.06 | O60 | Soft Anneal | Over 0.03 | F | 80 | 0.025 | 0.06 | O50 | Light Anneal | Up to 0.03 | 30T | 60 | A | 0.035 | O50 | Light Anneal | Over 0.03 | F | 90 | A | 0.035 | C27000/CuZn35 C27200/CuZn37 C27400/CuZn32 | O60 | Soft Anneal | Up to 0.03 | 30T | 40 | 0.025 | 0.06 | O60 | Soft Anneal | Over 0.03 | F | 80 | 0.025 | 0.06 | O50 | Light Anneal | Up to 0.03 | 30T | 60 | A | 0.035 | O50 | Light Anneal | Over 0.03 | F | 90 | A | 0.035 | C44300/CuZn28Sn | O60 | Soft Anneal | Up to 0.03 | 30T | 40 | 0.025 | 0.06 | O60 | Soft Anneal | Over 0.03 | F | 80 | 0.025 | 0.06 | O50 | Light Anneal | Up to 0.03 | 30T | 60 | A | 0.035 | O50 | Light Anneal | Over 0.03 | F | 90 | A | 0.035 |

A Although no Min. Grain size is specified, the products must nevertheless have a fully recrystallized grain structure |